enEnglisch

enEnglischAPPLICATION AREAS

Perfect for all processes where knowledge about the properties of combustible gas is crucial:

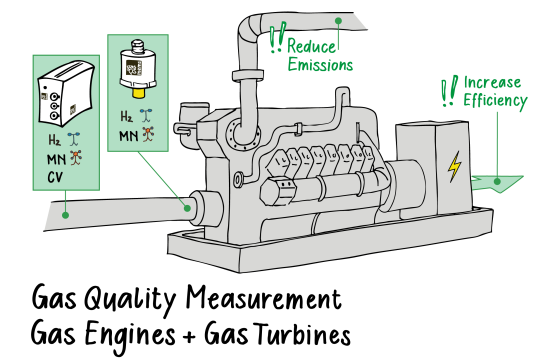

Gas Engines & Turbines

Maximum efficiency through smart gas quality measurement

Are you still waiting – or already optimizing?

The efficiency of gas engines and turbines depends heavily on gas quality. Failing to adapt operating parameters can lead to inefficient performance – and with hydrogen blends, incorrect settings can even cause damage. But gas quality is dynamic and ever-changing!

gasQS flonic & gasQS static provide fast and precise real-time data, enabling the automatic optimization of operating parameters.

Real-world example: One sensor improves 20 gas engines

At the coastal power plant in Kiel, a single gasQS flonic optimizes 20 gas engines – delivering efficiency gains that pay off after just three months!

If you want to future-proof your gas-powered systems, smart sensors are the way to go!

gasQS™ flonic

Perfect for power plants – optimizes multiple gas engines or turbines with just one measurement!

gasQS™ static

Mounted directly on the engine block – detects H₂ content in seconds (T90: 1–2s)!

Testimonials

Biogas plants

Efficient biomethane production with smart sensor technology

Sustainability requires precision!

Biogas is a key technology in the energy transition. But ensuring quality remains a challenge for many operators:

- How can you ensure that your biomethane complies with grid standards?

- How can methane slip be minimized while increasing efficiency?

The answer: gasQS™ static

The maintenance-free sensor for fast and reliable methane detection in biomethane and off-gas.

- ATEX certified – safe to use directly in the plant

- T90 of 1–2 seconds – instantly detects methane fluctuations

- Maintenance-free & durable – no sensor wear, no drift

- Cost-efficient & easily integrable

Why make it complicated when it can be smart?

With gasQS static, you optimize your biogas plant efficiently and sustainably.

Testimonials

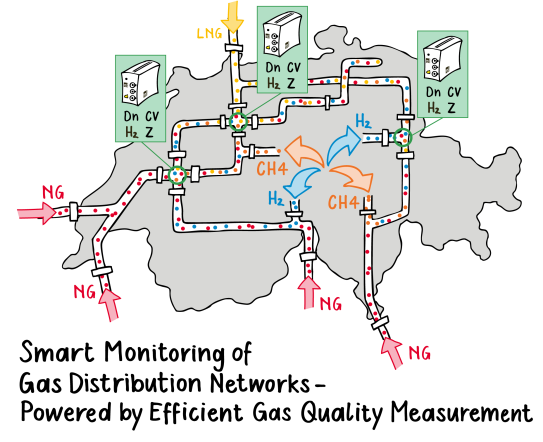

Gas distribution networks

Precise measurement for reliable gas quality

How accurate is your gas quality measurement?

In gas distribution networks, accurate determination of gas quality and volume is essential for precise billing and safe operation. However, traditional gas chromatographs (GCs) are often expensive, require intensive maintenance, and are unsuitable for decentralized measurement.

The solution: gasQS™ flonic

The gasQS flonic delivers high-precision measurements of calorific value, heating value, hydrogen content, and more – in a cost-effective, low-maintenance, real-time solution. With OIML R140 certification and ultra-low power consumption (<1.5W), it's ideal for modern gas grids, including those with up to 23% hydrogen.

Boost efficiency, reduce costs, and prepare your network infrastructure for the future!

Stimmen aus der Praxis

Areas in which our measuring equipment is successfully used:

- Management of the fermentation process

- Determination of the methane content in the product gas

- Determination of the methane content in the off-gas

- Automation of conditioning processes

- Calorific value monitoring of biogas infeeds

- Determination of gas indicators such as calorific value, density and real gas factors

- Determination of the hydrogen content

- Management of hydrogen infeed systems

- Monitoring reconstruction systems

- Calorific value monitoring of biogas infeeds

- Efficiency optimization in CHP plants

- Calorific value and methane number monitoring on engine test benches

- Higher performance in transportation

- Increase in operational safety

- Lower emission values

- Precise purity measurement of 98-100 mol% H₂

- Measurement in carrier gases such as N₂, O₂, air or argon

- Accuracy: ±0.05 mol%

- Detection of 0-2 mol% H₂ in the same carrier gases also possible

- Ideal for quality monitoring and process control

- No ppm detection - focus on technically relevant concentration ranges

We would be happy to provide you with a personal quote

Marco Siragna

Head of Sales gasQS™

Phone: +41 (0)56 481 90 75